Slope compactor rollers are indispensable in modern construction, offering precision and power to stabilize sloped terrains. Whether for road construction, embankments, or mining, these machines ensure durability and safety. This guide dives deep into their mechanics, applications, and best practices, equipping you with knowledge to optimize your projects.

What is a Slope Compactor Roller?

A slope compactor roller is a heavy-duty machine designed to compact soil, gravel, asphalt, or subgrade materials on inclined surfaces. Unlike flat-surface compactors, they feature specialized designs to prevent rollovers and enhance traction on steep grades .

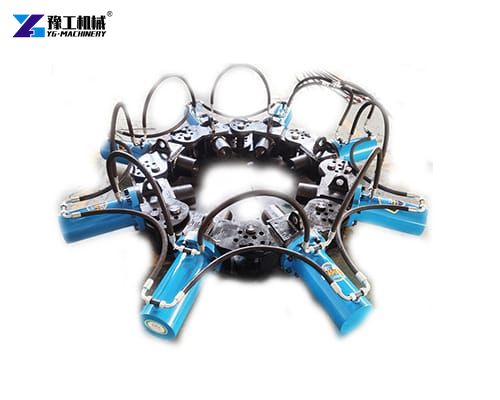

Main Components of Excavator Compactor Roller

- Drum: Equipped with vibratory mechanisms for dynamic compaction.

- Engine: Provides power for vibration and mobility.

- Counterweights: Improve stability on uneven terrain.

- Operator Cabin: Ergonomically designed for visibility and safety.

Why Slope Compaction is Challenging?

Compacting slopes requires overcoming gravity, which can cause material slippage. Poor compaction leads to erosion, landslides, or structural failure. Slope compactor rollers address this through:

- Centrifugal Force: Generated by vibratory drums to penetrate soil layers.

- Traction Control: Enhanced tread patterns or crawler tracks for grip.

- Articulated Frames: Allow maneuverability on tight curves.