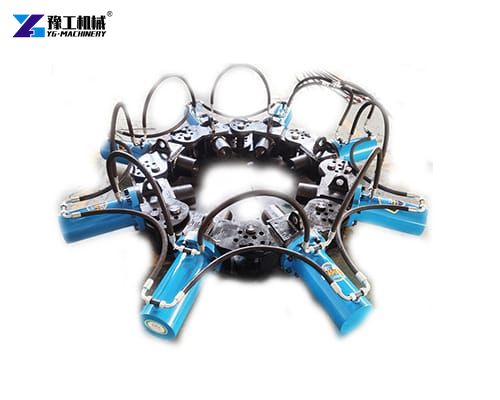

Rotary screening bucket is an attachment designed for excavators and other heavy machinery. It features a rotating drum with perforated screens that sift through materials, allowing smaller particles to pass through while retaining larger debris. This innovative design enables on-site screening, eliminating the need for multiple machines or manual sorting processes.

Benefits of Using A Rotating Screening Bucket

Versatility:

Screen different materials such as soil, sand, gravel, stones, rubble, and organic waste.

Suitable for various applications, including landscaping, pipeline laying, foundation preparation, and waste recycling.

Efficiency:

Rotary screening bucket reduces the need for additional screening equipment or manual labor.

Allows continuous operation, saving time and increasing productivity.

Precision:

Adjustable screen sizes allow for precise control over the output material size.

Ensures consistent quality of screened materials.

Durability:

Constructed from high-strength steel and wear-resistant components for long-lasting performance.

Designed to withstand harsh working conditions and heavy loads.

Applications of Rotary Screening Buckets

Construction Sites:

Screening aggregate for concrete production.

Separating rebar and other debris from concrete rubble.

Landscaping Projects:

Preparing topsoil for planting.

Creating gravel paths or drainage systems.

Demolition Work:

Recycling construction and demolition waste.

Separating valuable materials from rubble for reuse.

How Does Rotary Sieve Bucket Work?

Step 1: Load material into the rotary screening bucket.

Step 2: Activate the hydraulic rotation. The internal drum spins.

Step 3: Screen: Fines fall through the mesh; oversize (rocks, debris) exits the rear.

Step 4: Repurpose: Use screened material immediately or stockpile.

How to Operate A Rotary Sieve Bucket?

Operating a rotary screening bucket is simple and efficient:

Mount the Bucket: Attach to the machine using the quick coupler system.

Engage the Hydraulics: Power the rotary drum through the carrier’s hydraulic lines.

Screen Materials: Scoop and screen in a single motion, allowing fine material to fall through.

Unload Oversized Debris: Retained materials can be dumped in a separate pile for further processing or disposal.