Rock breaker attachment for excavator is a hydraulic-powered tool designed to be mounted on the arm of an excavator. It consists of a hammer mechanism that delivers repeated impacts to break apart materials. These attachments come in various sizes and configurations to suit different excavator models and applications. The primary components include the hammer body, piston, and tool bits, which work in harmony to deliver powerful blows.

Parameter of Excavator Rock Breaker Attachment

| Model | YGB200S | YGB600S | YGB900S | YGB1600S |

| Weight | 135kg | 410kg | 800kg | 1600kg |

| Length | 1100mm | 1528mm | 2260mm | 2695mm |

| Pressure | 90-120bar | 110-160bar | 150-170bar | 160-180bar |

| Flow | 20-40lpm | 50-90lpm | 80-120lpm | 120-160lpm |

| Rate | 700-1200bmp | 500-800bmp | 400-700bmp | 400-700bmp |

| Hose | 1/2inch | 1/2inch | 3/4inch | 1inch |

| Chisel | 45mm | 75mm | 100mm | 135mm |

| Suit | 1.2-3.0ton | 6-9ton | 11-16ton | 19-26ton |

Benefits of Using a Rock Breaker Attachment for Excavator

Incorporating a rock breaker attachment into your fleet offers numerous benefits, making it an invaluable asset for any construction or mining project:

- Suitable for Various Situations

Rock breaker attachments can be used on a variety of materials, from soft earth to hard rock. This versatility makes them a one-stop solution for many different tasks, reducing the need for specialized equipment. - Cost-Effectiveness

Purchasing a rock breaker attachment is often more cost-effective than buying a dedicated breaker machine. It allows you to utilize your existing excavator, minimizing capital expenditure and storage space. - Increased Efficiency

Rock breakers significantly boost productivity by quickly breaking down materials. They reduce manual labor and the time required to complete tasks, allowing you to complete projects faster and move on to the next one. - Enhanced Safety

Using a rock breaker attachment minimizes the risk of injuries associated with manual breaking. Operators remain in the safety of the excavator cab, protected from flying debris and other hazards.

Applications of Excavator Breaker Hammer

Rock breaker attachments are versatile tools with numerous applications across various industries:

- Mining: In mining, rock breaker attachments are used to break up overburden, extract minerals, and prepare the ground for further excavation. They are essential for breaking hard rock and ore.

- Construction: In construction, these attachments are used for demolition, trenching, and site preparation. They can break through concrete, asphalt, and rock to create foundations, roads, and other structures.

- Quarrying: Quarries rely on rock breaker attachments to extract materials like limestone, granite, and sandstone. They are used to break up large rocks into smaller, more manageable pieces.

Choosing the Right Rock Breaker Attachment

Selecting the right rock breaker attachment for your excavator involves considering several factors to ensure optimal performance and longevity:

1. Application Requirements: Consider the type of material you’ll be breaking and the level of force required. Harder materials like rock will necessitate a more powerful attachment than softer materials like asphalt.

2. Excavator Compatibility: Ensure the attachment is compatible with your excavator’s make, model, and hydraulic system. Different attachments are designed for specific excavator sizes and weight capacities.

Excavator Attachments in YG Machinery

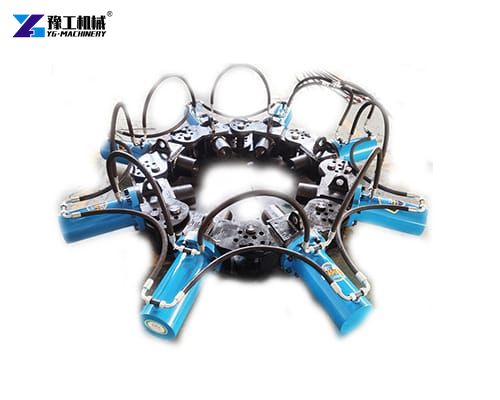

YG Machinery not only support the rock breaker attachment for excavator, but also the metal shear for excavator, car dismantling shears, concrete pile breaker, excavator orange peel grapple, excavator screening bucket for sale, excavator mounted pile driver, hydraulic quick hitch for sale, hydraulic magnet for excavator, slope compactor rollers, rotary drum cutter, , hydraulic ripper for excavator, and so on. If you are interested in these excavator attachments, please contact us freely.