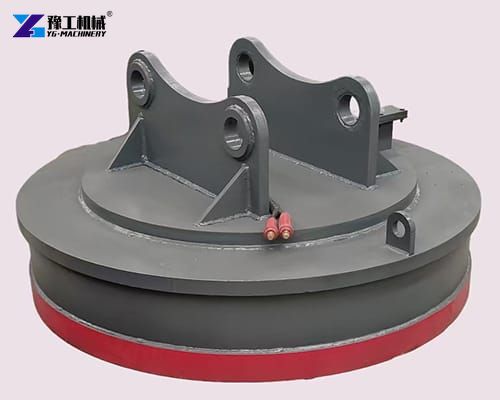

Electromagnetic lifter is a specialized lifting device that uses electromagnetic fields to attract and hold ferrous materials. It generates a magnetic force through an electric current. When activated, the device creates a strong magnetic field that adheres to metallic surfaces, allowing it to lift and move heavy loads without physical contact. Excavator magnets have become indispensable in steel plants, shipyards, scrap yards, warehouses, construction sites, and manufacturing facilities. They provide precision, safety, and cost-efficiency, making them one of the most widely adopted lifting solutions in the industrial sector.

Advantages Of Using Excavator Magnet

The benefits of using electromagnetic lifter extends far beyond their core features, delivering significant advantages that impact the bottom line.

- Increased Productivity: The speed and ease of use mean more material can be moved in less time, leading to higher output and faster project completion. This is especially critical in high-volume operations like scrap metal processing.

- Enhanced Safety: By reducing the need for manual handling of heavy materials and eliminating the risks associated with mechanical lifting equipment, it creates a safer work environment.

- Reduced Labor Costs: The efficiency of these lifters often means fewer personnel are needed to move the same amount of material, leading to lower labor costs.

- Versatility: They can lift a wide range of ferrous materials, including scrap metal, steel plates, pipes, and billets. Their ability to handle irregularly shaped items is a major plus.

Applications of the Electromagnetic Lifter

Excavator magnet attachments are widely used across industries where ferrous materials must be moved regularly:

- Steel manufacturing plants: The excavator magnet can be applied for lifting slabs, coils, and sheets.

- Shipbuilding yards: Handling steel plates for vessel construction.

- Scrap yards and recycling centers: Collecting and sorting ferrous scrap quickly.

- Engineering workshops: Moving raw materials and finished parts.

- Warehousing and logistics: Stacking steel products safely and efficiently.

Working Principle of Electronic Magnet

The working mechanism of an electromagnetic lifter is based on electromagnetic induction.

- Electric current flow: When current passes through the copper coil inside the lifter, it generates a magnetic field.

- Magnetic attraction: The ferrous material comes under the influence of this field and gets strongly attracted to the magnet.

- Holding force: The excavator magnet attachment securely holds the material as long as the current is supplied.

- Release mechanism: Once the current is cut off, the magnetic field collapses, and the material is released instantly.