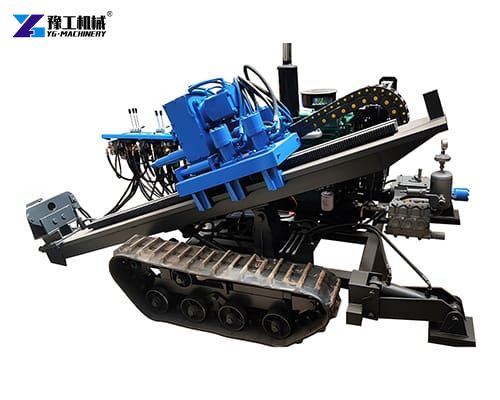

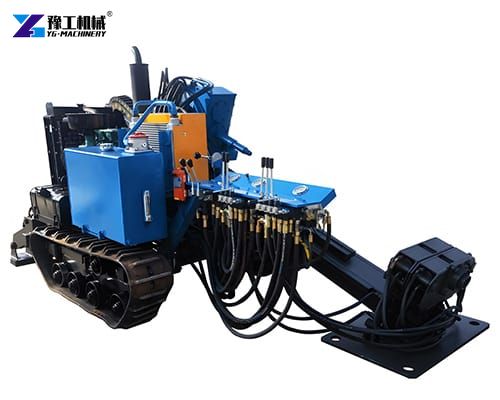

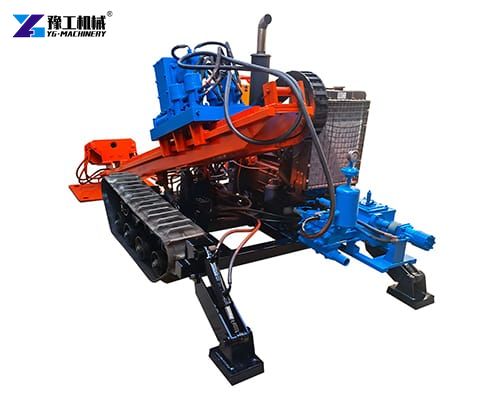

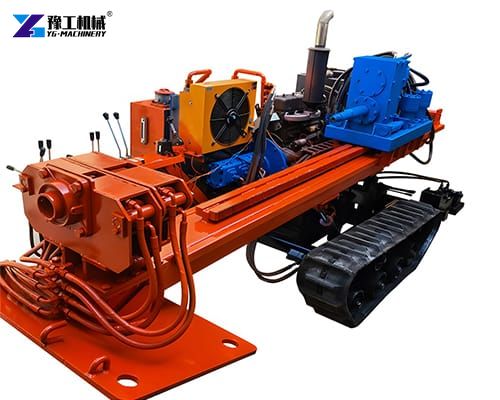

Horizontal directional drilling machine for sale uses a trenchless method to install underground utilities without the need for extensive excavation. Unlike traditional open-cut techniques, HDD involves drilling a pilot bore along a predetermined path, followed by reaming to enlarge the hole and finally pulling the product pipe or conduit through the drilled pathway. This process is guided by sophisticated tracking systems to ensure accuracy. HDD machines are engineered to handle diverse soil conditions from soft clay to hard rock. Their versatility makes them indispensable for projects requiring minimal surface disruption, such as urban areas, environmentally sensitive zones, or beneath existing infrastructure like roads and rivers.

Advantages of Horizontal Directional Drilling Machines

Investing in a horizontal directional drilling machine for sale offers numerous advantages that align with modern project demands:

- Minimal Environmental Impact

Traditional excavation methods often lead to landscape disruption, habitat destruction, and increased carbon emissions. HDD technology eliminates the need for large trenches, preserving ecosystems and reducing restoration costs. - Cost Efficiency

By avoiding extensive excavation, labor and equipment requirements are significantly reduced. Projects can be completed faster, lowering overall expenses. - Enhanced Safety

HDD minimizes risks associated with open trenches, such as collapses or accidents involving workers and pedestrians. - Versatility

These machines adapt to various terrains and soil types, enabling installations beneath obstacles like highways, railways, and water bodies. - Reduced Social Disruption

In densely populated areas, HDD prevents traffic congestion, noise pollution, and property damage associated with traditional digging methods.

Choosing the Right HDD Machine for Sale

Selecting an HDD machine requires careful evaluation of project needs and machine specifications. Below are critical factors to consider:

- Drilling Capacity

Machines are categorized by their maximum thrust pullback force and torque. Smaller rigs (10-50 tons) suit residential or light commercial projects while larger models (over 200 tons) handle cross-country pipelines or major infrastructure. - Depth and Distance Requirements

Evaluate the machine’s ability to achieve desired bore lengths and depths. Advanced rigs can drill up to 6000 feet with depths exceeding 150 feet. - Soil and Rock Conditions

Ensure the machine is equipped to handle specific ground conditions. Features like dual-pipe systems or rock drill heads may be necessary for hard formations. - Tracking and Guidance Systems

Modern HDD rigs integrate electronic tracking systems (e.g., walk-over or wire-line) to monitor drill head location and alignment in real time. - Power Source

Diesel-powered machines offer mobility and high torque, while electric models are quieter and eco-friendly, ideal for urban projects. - Portability and Setup Time

Compact rigs with modular designs reduce transportation costs and enable quick assembly on-site.