Hydraulic ripper for excavator is a specialized excavator attachment mounted on the arm or boom of an excavator. Hydraulic rippers use controlled vibrations and pressure to fracture materials. It is designed to tackle some of the toughest ground conditions. Whether the task is breaking frozen soil, hard rock, shale, or reinforced concrete, a hydraulic ripper enhances the productivity of excavators while reducing fuel consumption and operating costs.

Excavator Ripper Parameter

| Model | YGR02 | YGR04 | YGR06 | YGR08 | YGR10 | YGR14 |

| suitable excavator | 4-6T | 5-9T | 9-16T | 16-23T | 23-30T | 30-39T |

| pin to pin distance | 265mm | 310mm | 390mm | 465mm | 520mm | 570mm |

| overall width | 375mm | 420mm | 570mm | 665mm | 740mm | 820mm |

| overall height | 390mm | 950mm | 1180mm | 1260mm | 1380mm | 1470mm |

| pin diameter | 40-50mm | 50-55mm | 60-70mm | 70-80mm | 80-90mm | 80-90mm |

| dipper width | 150-180mm | 180-200mm | 200-315mm | 300-350mm | 360-420mm | 360-420mm |

| plate thickness | 50mm | 55mm | 65mm | 80mm | 90mm | 90mm |

| teeth model | DH55type | DH150type | DH220type | D85Ctype | 4T5502-2type | 4T5502-2type |

| weight | 60kg | 160kg | 245kg | 420kg | 620kg | 775kg |

Features of Hydraulic Ripper for Excavator

Vibration Technology: The tool utilizes high-frequency vibrations combined with strong impact energy to fracture and loosen hard materials.

Heavy-Duty Design: Built with wear-resistant steel and robust components, hydraulic rippers can withstand extreme conditions.

Compatibility: Available in different sizes, they can be matched to a wide range of excavators, from small to large-scale machines.

Energy Efficiency: The system harnesses hydraulic power more efficiently, reducing fuel usage compared to hydraulic breakers.

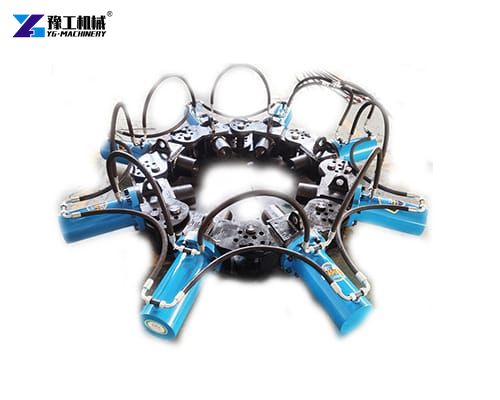

Components of a Hydraulic Ripper

To fully understand how a hydraulic ripper works, it’s important to be familiar with its key components. Here are the main parts of a hydraulic ripper:

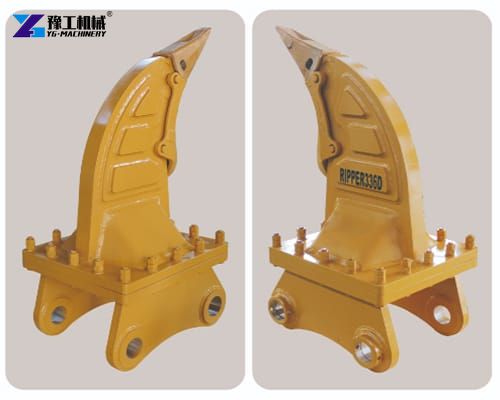

- Shank

The shank is the main body of the ripper. It’s a long, cylindrical piece of steel that connects the ripper to the excavator’s boom. The shank is designed to be strong and durable, capable of withstanding the forces involved in tearing through tough materials. - Teeth

Attached to the end of the shank are the teeth. These are the sharp, pointed pieces of steel that do the actual tearing. Teeth are typically made from high-strength alloy steel and are designed to be replaceable, so they can be easily swapped out when they become worn or damaged. - Hydraulic Cylinder

The hydraulic cylinder is the power source for the ripper. It’s mounted to the excavator’s boom and uses hydraulic pressure to drive the shank and teeth into the ground. The cylinder is capable of generating a significant amount of force, allowing the ripper to tear through even the toughest materials.

Working Principle of Excavator Ripper

The hydraulic ripper operates by combining hydraulic power with vibratory force. When connected to the excavator’s hydraulic system, the motor activates the vibration mechanism. This generates high-frequency oscillations transmitted to the ripper tooth. As the tooth penetrates rock, frozen ground, or concrete, the vibrations weaken the internal structure of the material, making it easier to fracture and break apart. This method requires less brute force than a hydraulic breaker, resulting in greater efficiency and reduced stress on the machine.

Common Applications of Hydraulic Rippers

- Demolition: Tearing through reinforced concrete and other materials to demolish structures.

- Trenching: Creating trenches for utilities and pipelines.

- Rock Excavation: Breaking up rock formations for mining and other purposes.

- Frozen Ground: Penetrating through frozen soil and ice.