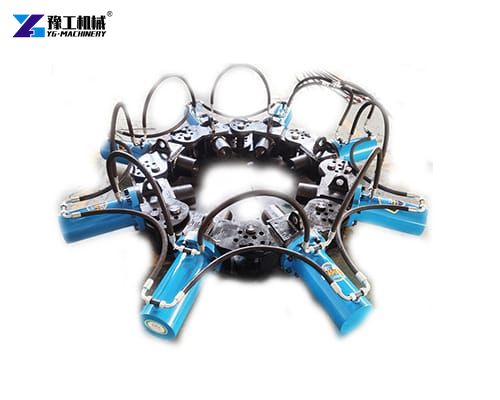

Hydraulic shears for excavator are specialized attachments designed to be mounted on the arm of an excavator. They utilize the excavator’s hydraulic system to generate immense cutting force, enabling them to slice through metal, concrete, and other tough materials with ease. The shears typically feature a pair of robust, high-strength steel blades that open and close in a scissor-like motion, driven by hydraulic cylinders. When it comes to breaking down steel structures, cutting through reinforced concrete, or dismantling vehicles, hydraulic shears for excavators emerge as the go-to solution. These powerful attachments, also known as excavator-mounted hydraulic shears or “eagle beak” shears, combine the mobility of excavators with the cutting force of hydraulic systems to deliver unparalleled performance in a variety of applications.

Components of the Excavator Shear Attachment

Hydraulic Cylinders: These are the powerhouses of the shears, converting hydraulic pressure into mechanical force to drive the blades’ movement. Dual-cylinder designs are common, ensuring synchronized and powerful cutting action.

Blades: Made from high-grade alloy steel, the blades are heat-treated for maximum hardness and durability. The hydraulic shears for excavator is designed to maintain sharpness over extended use and can be replaced or rotated to extend their lifespan.

Synchronization Mechanism: In dual-cylinder shears, a synchronization mechanism ensures that both cylinders operate in unison, preventing blade misalignment and ensuring clean, precise cuts.

Applications of Hydraulic Shears for Excavator

Demolition: From residential buildings to industrial complexes, hydraulic shears excel at breaking down concrete and steel structures quickly and safely.

Scrap Metal Recycling: In scrapyards, these shears are used to cut and process various metal scraps into manageable sizes for recycling.

Construction: During construction projects, these shears assist in modifying existing structures, removing unwanted elements, and preparing sites for new development.

Advantages of Metal Shear for Excavator

Exceptional Cutting Power: Harnessing your excavator’s hydraulic system, the hydraulic shears for excavator generate immense cutting force to cleanly slice through steel, rebar, concrete, pipes, and various scrap materials.

Built for Durability: Constructed from high-strength, wear-resistant steel, our excavator shears are designed to withstand extreme operating conditions, ensuring a long service life and minimal downtime.

Versatile Applications: From primary demolition and structural dismantling to scrap metal recycling and concrete crushing, our hydraulic shears are adaptable to diverse tasks.

How to Choose the Right Hydraulic Shears for Your Excavator?

When selecting hydraulic shears for your excavator, consider the following factors:

Cutting Capacity: Choose shears with a cutting capacity that matches the thickness and hardness of the materials you’ll be cutting.

Excavator Compatibility: Ensure that the shears are compatible with your excavator’s hydraulic system and mounting specifications.

Blades Quality: Opt for shears with high-quality, durable blades that can withstand the demands of your applications.