Laser concrete screed machine combines cutting-edge laser guidance systems with mechanical engineering to achieve unprecedented levels of precision and efficiency. This automated equipment uses laser technology to create perfectly level concrete surfaces with minimal human intervention. With applications spanning industrial plants, warehouses, distribution centers, and large-scale infrastructure projects, the concrete laser screed machine has become indispensable in modern construction where dimensional accuracy, surface flatness, and long-term durability are paramount.

Technical Composition

The structural design of a laser concrete screed machine integrates several critical components that work synergistically to achieve optimal performance. At its core lies the laser transmitter, which projects a precise horizontal or tilted reference plane across the construction area. This beam is detected by the laser receiver mounted on the machine, which continuously monitors its position relative to the reference plane. The data from the receiver feeds into the intelligent control system, which adjusts the machine’s operating parameters in real time to maintain exacting tolerances.

Features of the Laser Concrete Leveling Machine

- One of the most remarkable features of the laser concrete screed machine is its exceptional accuracy. Laser sensors detect minute changes in elevation and transmit signals to the control system, which adjusts the screed blade accordingly.

- Another important feature is automation. The machine significantly reduces the need for manual labor, allowing one operator to control a large working area. This not only improves efficiency but also reduces labor costs and human error.

- High efficiency is also a defining feature. Concrete laser leveling machine can level hundreds or even thousands of square meters of concrete in a single day, far surpassing traditional methods.

- Durability and adaptability further enhance its appeal. Most machines are built with robust steel frames and powerful engines, enabling them to work in harsh construction environments and handle different concrete mixes.

Concrete Laser Leveling Machine Applications

- The laser concrete screed machine is widely used in industrial flooring projects where flatness and load bearing capacity are critical. Factories producing heavy machinery, automotive plants, and steel processing facilities rely on precise concrete floors to support equipment and ensure operational safety.

- Warehouses and logistics centers are another major application area. High flatness floors allow forklifts and automated guided vehicles to operate smoothly, reducing maintenance costs and improving efficiency.

- Commercial buildings such as shopping malls, exhibition halls, and parking garages also benefit from laser screeding technology. The smooth surface enhances aesthetics and durability while shortening construction timelines.

Comprehensive Structure And Components

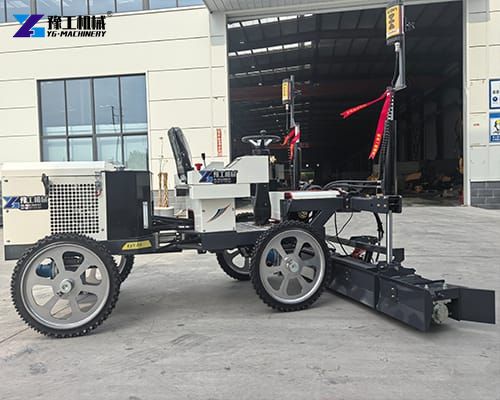

- The Chassis and Drive System: This is the backbone of the machine. It usually features high flotation tires to minimize the footprint on the subgrade or the reinforcement mesh.

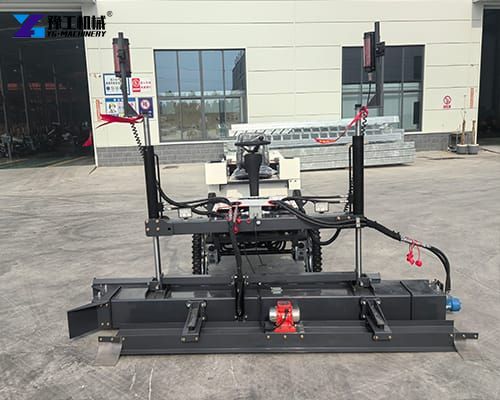

- Laser Receivers: Mounted on the screed head, these sensors pick up the signal from the transmitter. They communicate with the machine’s hydraulic system to adjust the height of the screed.

- The Screed Head: This is the business end of the machine. It typically consists of an auger that moves excess concrete to the side, a vibrator for consolidation, and a leveling blade that strikes off the concrete to the desired height.

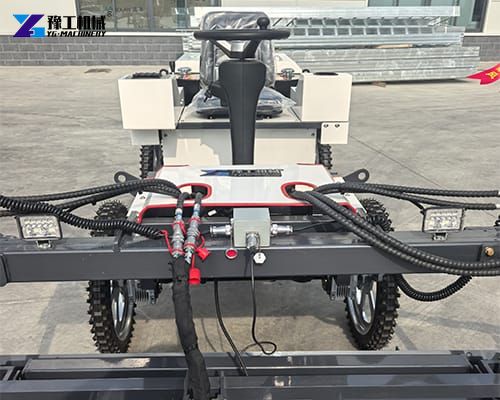

- Control Console: This is where the operator interacts with the machine. It features joysticks, digital displays, and diagnostic tools to monitor the leveling process in real time.

- Hydraulic System: The power behind the movement. Hydraulics control the boom extension, the elevation of the screed head, and the propulsion of the wheels.

Maintenance and Longevity Strategies

- To ensure a long service life for a laser concrete screed machine, a rigorous maintenance schedule is mandatory. The most critical aspect is cleaning. Concrete starts to harden as soon as it is placed. After every shift, the screed head, auger, and vibrator must be thoroughly washed down to prevent buildup that can jam moving parts or affect the leveling accuracy.

- Hydraulic systems should be checked daily for leaks, and oil filters must be changed according to the recommendations. The laser sensors are sensitive instruments; they should be stored in protective cases when not in use and checked for calibration regularly.

- Engine maintenance follows standard industrial protocols: checking coolant levels, air filters, and fuel quality. Because these machines often operate in dusty environments, air filters may need more frequent attention than in other applications.