Photovoltaic pile driver is a machine specifically designed for the installation of foundation piles used in solar power plants. These piles, made of metal or concrete, serve as the structural base for solar panels. Solar pile drivers drive these piles deep into the ground, ensuring a secure foundation for the solar panel mounting system. Unlike traditional pile drivers used in general construction, photovoltaic piling machine prioritize adaptability to varying soil conditions, reduced energy consumption, and compatibility with solar-specific foundation designs. It is crucial in solar projects, especially large-scale installations, where the ground needs to be properly prepared to support the weight and structure of the solar arrays. The pile driver ensures that the foundations are securely placed, minimizing the risk of structural instability or failure over time.

Components of a Photovoltaic Pile Driver

Hydraulic or Electric Drive System: Modern photovoltaic piling drivers often use hydraulic or electric systems to generate the force required to insert piles.

Guidance and Positioning Technology: Advanced GPS and laser-guided systems ensure piles are installed at exact angles and depths, critical for maintaining the uniformity of solar arrays.

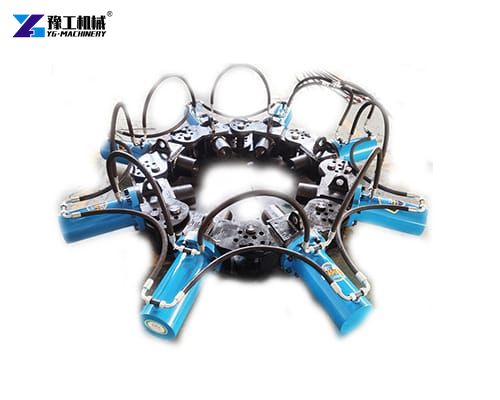

Pile Gripping Mechanism: Adjustable clamps secure piles during installation, accommodating different diameters and materials such as steel, concrete, or composite.

Mobility Features: Tracked or wheeled chassis enable movement across uneven or soft terrain, reducing the need for site preparation.

Advantages of Solar Pile Drivers

- Enhanced Efficiency and Speed

Solar farms often require thousands of piles to be installed within tight timelines. Photovoltaic pile drivers can complete a pile installation in minutes, significantly accelerating project schedules compared to manual methods. - Precision and Consistency

Automated alignment systems ensure each pile is positioned accurately, maintaining the geometric integrity of solar arrays. This precision maximizes energy output by minimizing shading and alignment errors. - Reduced Environmental Impact

By minimizing soil disturbance and avoiding extensive excavation, it helps preserve local ecosystems. Electric models further reduce carbon footprints by eliminating diesel emissions.

Working Principle of Photovoltaic Piling Machine

Photovoltaic pile drivers operate using advanced hydraulic systems that deliver high force to drive piles into the ground. The process begins with the machine positioning itself over the designated installation site. A pile, typically made of galvanized steel or other durable materials, is then inserted into the machine’s mechanism.

Once the pile is in place, the pile driver uses hydraulic force to push the pile deep into the ground. The machine is capable of adjusting the force based on the soil condition, ensuring optimal penetration without causing damage to the pile or surrounding environment. The pile driver also ensures that the piles are installed at the correct angle and depth, which is essential for the stability of the entire solar installation.

In some cases, photovoltaic pile drivers can be equipped with advanced vibration damping systems to reduce the noise and vibration caused during the pile-driving process. This makes the machines more suitable for urban and environmentally sensitive areas where noise pollution is a concern.