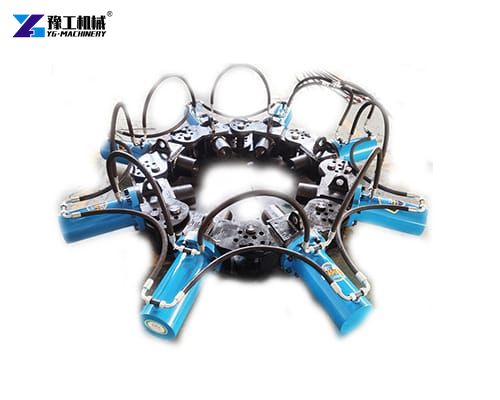

Pile breaker is a hydraulic excavator attachment designed to remove the exposed upper sections of concrete or steel piles after pile driving or drilling operations. It is also known as a hydraulic pile cutter or pile crusher. This machine integrates seamlessly with excavators to deliver rapid, clean, and cost-effective pile removal solutions. Among the many specialized tools that drive progress, pile breaking machine machines stand out as critical equipment for foundation work. These robust machines are designed to dismantle concrete piles efficiently, ensuring structural integrity while saving time and labor costs.

Advantages of Using a Pile Breaker

The hydraulic pile cutter offers numerous benefits over traditional pile cutting methods, making it an essential tool in modern construction:

High Efficiency: Speeds up the pile breaking process significantly, saving time and labor.

Cost-Effective: Reduces the need for manual labor and minimizes material waste.

Safety: Eliminates the risk associated with manual cutting tools and heavy hammering.

Minimal Noise and Vibration: Causes less disturbance to surrounding structures and environments.

Eco-Friendly: Generates less dust and debris compared to conventional breaking methods.

How Does An Excavator Pile Cutter Work?

- Attachment: The machine is mounted onto an excavator’s arm using a quick-coupler system.

- Positioning: The operator lowers the pile breaker over the target pile, aligning the blades with the pile’s circumference.

- Cutting: Hydraulic pressure forces the blades inward, cracking the concrete or steel in a controlled manner.

- Ejection: After cutting, the broken pile segment is removed, and the process repeats until the desired depth is achieved.

Applications Of Pile Breaking Machine

Pile breaker machines are indispensable across multiple sectors:

- High-Rise Buildings: Trim excess pile height to prepare for podium slabs or basements.

- Bridges and Flyovers: Remove temporary support piles after completion.

- Marine Construction: Break underwater piles without damaging surrounding structures.

- Urban Infrastructure: Facilitate pile removal in densely populated areas with minimal disruption.

- Demolition Projects: Dismantle outdated foundations for redevelopment.

Factors to Consider When Choosing A Concrete Pile Cutter

Selecting the right concrete pile breaker for a project is crucial for maximizing efficiency and achieving the desired results. Several factors should be taken into account:

Pile Diameter and Shape: It must be compatible with the size and shape (round, square) of the concrete piles being used on the project. Ensure that the chosen model has the appropriate operating range.

Concrete Strength: The compressive strength of the concrete in the piles can influence the type and power of the concrete pile cutter required. Higher strength concrete may necessitate a more robust breaking mechanism.

Project Scale and Timeline: For large-scale projects with tight deadlines, the efficiency of the pile breaking machine becomes a significant factor. Hydraulic models generally offer faster breaking cycles.

Excavator Compatibility: It needs to be compatible with the excavator that will be used to operate it. Consider the excavator’s hydraulic capacity and the weight of the pile breaker.