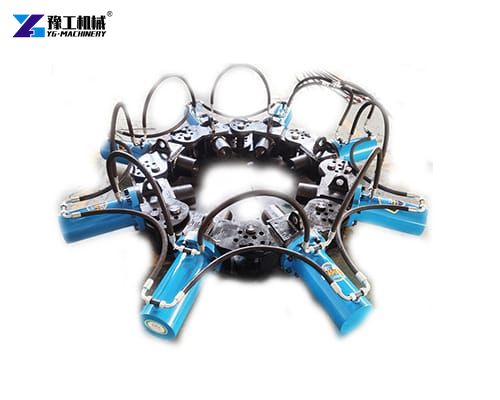

Pile breaking machine, also known as a pile cutter, is a specialized construction device used to break down concrete piles, sheet piles, or other foundational structures after they have served their purpose or during redevelopment projects. Traditional methods of pile removal, such as manual hammering or explosive demolition, are labor-intensive, time-consuming, and pose significant safety risks. In contrast, concrete pile breaker offers a safer, faster, and more environmentally friendly solution. There are different types that can handle various pile shapes and sizes, including round, square, and rectangular piles. With the use of hydraulic cylinders and modular chains or clamps, these machines break concrete accurately while minimizing damage to the reinforcement bars inside.

Advantages of Using a Pile Breaking Machine

- High Efficiency

Traditional pile breaking methods could take hours or even days per pile, depending on its size and material. Hydraulic pile breaker reduces this time to minutes, with some models capable of processing multiple piles in a single workday. This acceleration directly translates to shorter project timelines and reduced labor costs. - Enhanced Safety

Manual pile breaking exposes workers to hazards like falling debris, vibrations, and toxic fumes from burning processes. By automating the task, pile breaking machines eliminate these risks, creating a safer work environment and reducing insurance liabilities. - Cost-Effectiveness

While the upfront investment in a concrete pile breaker may seem significant, the long-term savings are substantial. Faster completion times, minimized material waste, and reduced need for skilled labor contribute to a rapid return on investment.

Main Applications of Hydraulic Pile Breaker

- Building Demolition

Removing old foundations to make way for new structures - Bridge and Highway Construction

Clearing piles from previous infrastructure to accommodate expansions or repairs - Port and Harbor Projects

Dismantling sheet piles used in temporary cofferdams or seawalls - Environmental Remediation

Safely removing contaminated piles to prevent ecological harm

Choosing the Right Concrete Pile Breaker for Your Project

- Pile Material and Diameter

Concrete and steel piles demand different cutting mechanisms. Ensure the machine’s specifications match your project’s pile dimensions and material composition. - Power Source

The pile breaking machine may be hydraulic powered by excavators or dedicated power packs. - Mobility and Size

Compact models are suitable for confined spaces, while larger units handle heavy-duty applications.

Maintenance Tips for Longevity

To maximize the lifespan of a pile breaking machine, adhere to these maintenance practices

- Regularly inspect hydraulic hoses and connections for leaks

- Lubricate moving parts to prevent wear and tear

- Clean tools after use to avoid concrete buildup

- Schedule professional servicing to address complex issues