Rotary drum cutter is a heavy-duty attachment mounted on excavators, hydraulic rigs, or specialized machinery. It features a cylindrical drum embedded with durable carbide or diamond-tipped teeth that rotate at high speeds to cut, grind, or demolish tough materials. Unlike traditional methods (e.g., jackhammers or explosives), drum cutters deliver precise, vibration-free results, making them ideal for sensitive environments.

Key Components of Rotary Drum Cutter

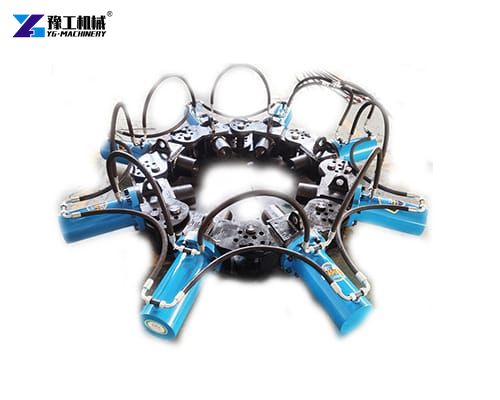

- Drum: The core cylinder, available in diameters from 300 mm to 1,500 mm, determines cutting depth and width.

- Cutting Teeth: Interchangeable tungsten carbide or diamond picks designed for specific materials.

- Drive System: Hydraulic motors power the drum’s rotation.

- Mounting Frame: Connects the cutter to machinery, ensuring stability and alignment.

- Cooling System: Prevents overheating during prolonged use.

Applications of Rotary Drum Cutters

From urban construction to mining, drum cutters excel in diverse scenarios:

- Trenching and Excavation

Cut precise trenches for utilities, pipelines, or drainage systems. Ideal for rocky or mixed soil where conventional buckets fail. - Demolition

Remove concrete foundations, bridge decks, or industrial floors without damaging adjacent structures. - Mining and Quarrying

Profile mine walls, create benches, or extract minerals with minimal waste. - Tunnel Boring

Smooth tunnel surfaces and correct over breaks in hard rock tunneling projects. - Asphalt Milling

Recycle road surfaces by milling asphalt layers to exact depths.