Water well drilling rig machine is a specialized piece of equipment designed to bore holes into the earth’s surface to access groundwater. These machines are essential in various sectors, including agriculture, municipal water supply, and industrial applications. The process of drilling a well involves penetrating layers of soil and rock to reach an aquifer, a permeable layer of rock or sediment that holds groundwater.

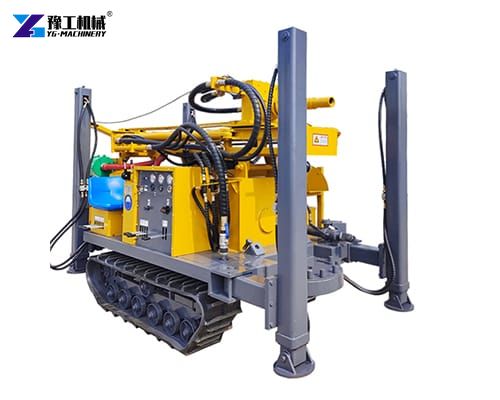

150m and 200m Water Well Drilling Rig Machine

| Model | YG-150 | YG-200 |

| Max Drilling Depth | 150m | 200m |

| Hole Diameter | Φ130-254mm | Φ130-254mm |

| Drilling Pipe Diameter | Φ76/89mm | Φ76/89mm |

| Drilling Pipe Length | 3m | 3m |

| Rig Lifting Force | 12Ton | 15Ton |

| Rotating Torque | 3500-3800Nm | 4000-4600Nm |

| Rotating Speed | 40-65r/min | 45-65r/min |

| Engine Power Diesel | 42KW | 58KW |

| Working Air Pressure | 1.7-2.5MPa | 1.7-2.5MPa |

| Air Consumption | 17-31m3/min | 17-31m3/min |

| Dimensions | 3500*1700*2250mm | 3800*1700*2250mm |

| Weight | 4500kg | 4500kg |

Operational Mechanisms

The operational mechanisms of water well drilling rig machines can vary depending on the type of rig. However, most rigs follow a general procedure:

- Site Preparation:

Clear the area of obstructions and level the ground to ensure stability.

Set up the rig and position it accurately over the drilling location. - Rig Assembly:

Erect the mast or derrick and secure it.

Connect the drill pipe and attach the appropriate drill bit. - Drilling Commencement:

Start the power source and engage the rotary drive system to begin rotating the drill bit.

Lower the drill bit into the ground and apply steady pressure to initiate cutting. - Mud Circulation:

Activate the mud pump to circulate drilling fluid through the drill pipe and bit.

Monitor the return flow of mud and cuttings to the surface for analysis. - Drilling Progress:

Continuously add drill pipe sections as the hole deepens.

Adjust drilling parameters (such as rotation speed and mud flow rate) as needed based on formation conditions. - Completion and Casing:

Once the desired depth is reached, retrieve the drill bit and insert casing to line the well.

Secure the casing with cement or other suitable materials to prevent collapse and contamination. - Development and Testing:

Pump water into the well to flush out any remaining debris.

Perform tests to assess the well’s yield and quality.

Maintenance Tips for Water Well Drilling Rig Machines

Proper maintenance is crucial for extending the lifespan of your water well drilling rig machine and ensuring optimal performance. Here are some essential maintenance tips:

- Regular Inspections:

Conduct daily, weekly, and monthly inspections to identify and address potential issues promptly.

Check for signs of wear, damage, or leaks in hoses, pipes, and connections. - Lubrication:

Keep all moving parts well-lubricated to reduce friction and wear.

Follow the manufacturer’s recommendations for lubrication intervals and types of lubricants. - Cleaning:

Clean the rig thoroughly after each use to remove mud, debris, and other contaminants.

Pay special attention to the mud pump, drill bits, and circulation system. - Filter and Fluid Changes:

Regularly change the oil and filters in the power source and hydraulic systems.

Maintain the cleanliness and quality of drilling fluids to prevent equipment damage. - Storage:

Store the rig in a dry, protected area when not in use to prevent rust and corrosion.

Cover the rig to shield it from dust, moisture, and UV exposure. - Repairs and Replacements:

Address any damaged or worn-out parts immediately to prevent further damage.

Replace drill bits and other consumables as needed to maintain drilling efficiency. - Operator Training:

Ensure that operators are trained and familiar with the rig’s operation, maintenance procedures, and safety protocols.

Encourage operators to report any issues or anomalies during use.